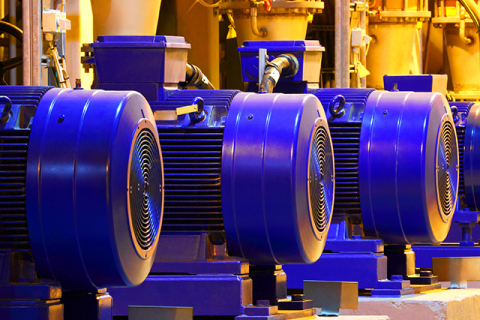

Importance of Variable Frequency Drives (VFD) in Water and Pump Systems

In the modern world, efficient management of water resources is crucial. Whether for agricultural irrigation, municipal water supply, or industrial processes, the need for efficient and reliable water and pump systems is paramount. One of the key technologies driving this efficiency is the Variable Frequency Drive (VFD). This article explores the importance of VFDs in water and pump systems, highlighting their benefits, applications, and the transformative impact they have on energy consumption and system performance.

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of electric motors by varying the frequency and voltage of the power supplied to them. VFDs are widely used in various industries to enhance the performance and efficiency of motor-driven equipment.

Key Components of a VFD

- Rectifier: Converts incoming AC power to DC power.

- DC Bus: Filters and stores the DC power.

- Inverter: Converts DC power back to AC at the required frequency and voltage.

- Controller: Manages the operation of the VFD, allowing for precise control of motor speed.

Benefits of VFDs in Water and Pump Systems

1. Energy Efficiency

One of the most significant advantages of using VFDs in water and pump systems is improved energy efficiency. Traditional pump systems often operate at full speed regardless of demand, leading to unnecessary energy consumption. VFDs adjust the motor speed to match the actual demand, significantly reducing energy use. This can lead to energy savings of up to 50% in some applications.

2. Enhanced Control

VFDs provide precise control over pump speed and pressure. This precise control allows for better management of water flow and pressure, reducing wear and tear on the system and extending the lifespan of the equipment. It also ensures that the system operates within optimal parameters, preventing issues such as water hammer and cavitation.

3. Cost Savings

The initial investment in VFD technology can be offset by the long-term cost savings. Reduced energy consumption leads to lower utility bills, and the extended lifespan of the equipment reduces maintenance and replacement costs. Additionally, VFDs can help avoid costly downtime by providing smoother and more reliable operation.

4. Environmental Benefits

By reducing energy consumption, VFDs help lower greenhouse gas emissions. This is particularly important in large-scale water and pump systems, where the cumulative impact on the environment can be significant. Implementing VFDs contributes to sustainability goals and helps organizations reduce their carbon footprint.

5. Improved System Reliability

VFDs enhance the reliability of water and pump systems by providing soft-start capabilities, which reduce mechanical stress on the pumps and associated infrastructure. This leads to fewer breakdowns and interruptions, ensuring a more consistent and dependable water supply.

Applications of VFDs in Water and Pump Systems

1. Municipal Water Supply

In municipal water systems, VFDs are used to regulate the speed of pumps that distribute water throughout the community. This ensures a stable water pressure and prevents the system from overloading during peak demand periods.

2. Irrigation Systems

For agricultural applications, VFDs optimize the performance of irrigation pumps, ensuring that crops receive the right amount of water without wasting energy. This is especially beneficial in regions with limited water resources, where efficient water management is critical.

3. Industrial Processes

In industrial settings, VFDs are used to control the pumps that supply water for cooling, cleaning, and other processes. This helps maintain consistent process conditions and improves the overall efficiency of the operation.

4. Wastewater Treatment

VFDs play a crucial role in wastewater treatment plants by controlling the speed of pumps that move wastewater through the treatment process. This ensures that the system operates efficiently and meets regulatory standards for effluent quality.

Conclusion

The adoption of Variable Frequency Drives in water and pump systems represents a significant advancement in the quest for efficiency and sustainability. By optimizing energy use, enhancing system control, and improving reliability, VFDs offer numerous benefits that translate into cost savings and environmental advantages. As the demand for efficient water management continues to grow, the importance of VFDs in ensuring the reliable and sustainable operation of water and pump systems cannot be overstated. Investing in VFD technology is not just a smart economic decision; it is a crucial step toward a more sustainable future.

Leave a comment