1. Maximized User Convenience

Communication Module

- RS-485 Capability is built-in

- Modbus-RTU, Metasys N2

- BACnet MS/TP is embedded as standard

- LonWorks option can be added

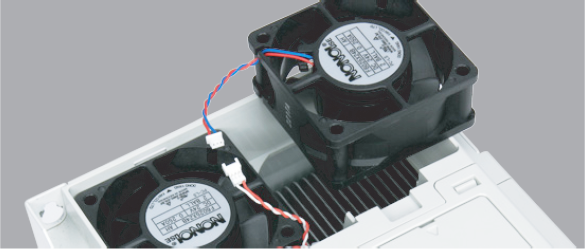

Easy to Change Cooling Fan

It is easy to change the cooling fan

without opening the cover of the drive

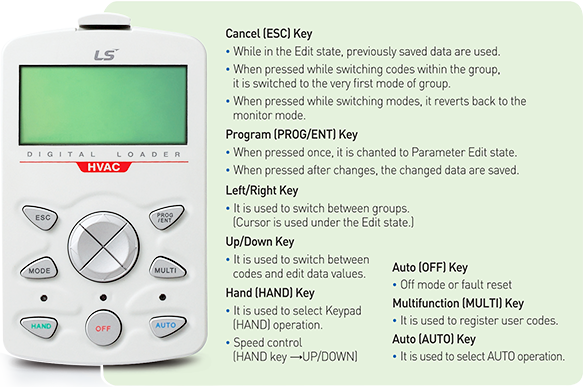

Keypad Exclusive for HVAC

Used to issue commands, configure drive parameters, and for monitoring drive status

- HAND mode (Local, Control, Mode) or AUTO Mode (Remote Control Mode) may be selected.

- HAND Mode: Used when selecting frequency or run/stop commands.

- AUTO Mode: Drive operated using the keypad. Multifunctional terminal block and communications.

- Fault Status Monitoring

Specification Level Option (Conduit Kit)

Acquired UL open type & enclosed type 1 certification

- When the conduit option is used, the drive meets UL Enclosed Type 1 specifications

Flange Type

If the space is too small, a heat sink can be installed outside the panel

DC Reactor

A built-in DC reactor to improve power factors and reduce THD is installed.

- DC Reactor built-in as a standard for 400V 37-90kW

Built-in EMC Filter

A built-in EMC filter to respond to the specifications for noise reduction

- 400V 0.75~30kW Built-in as default (C3)

- 400V 37~55kW Built-in option can be selected (C3)

※ 75~90kW satisfies EMC specifications even without a filter

Compliant with Global Specifications

UL Plenum Rated

(American standards for conditional fire safety)

※ Suitable for installation in compartments handing conditioned air

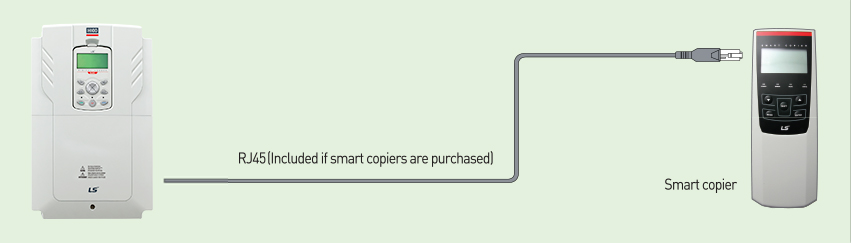

Smart Copier

- Power-free Operation

- LED Feedback

- Parameters Read/Write

- Easy to Install

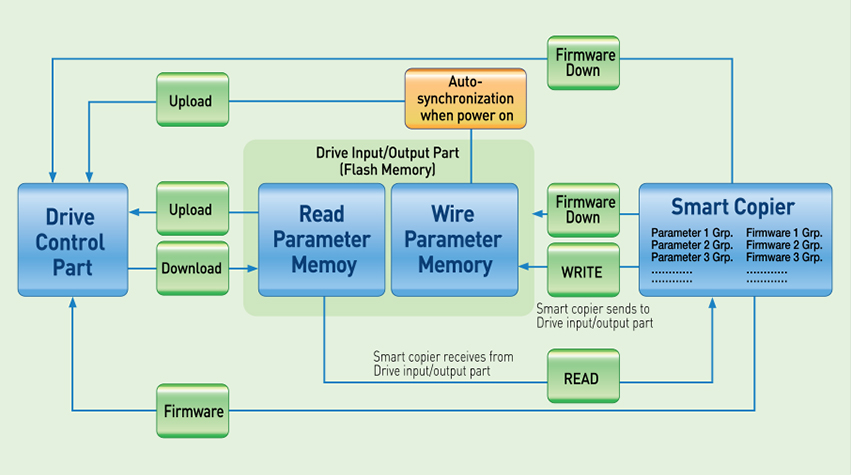

Data Flow in Smart Copier

2. Efficient Use of Space

Side-by-Side Installation

The size of the control board is significantly reduced when multiple drives are installed by minimizing the distance between products installed

※Side-by-side installation is unavailable for 37~90kW

Reduced Size

Main components are optimally deployed through thermal radiation analysis and 3D design to reduce size by 34% compared to iP5A (Volume based)

3. Stable System Control

LSLV-H100 drives are intelligent drives equipped with various protective and operation functions for continuous stable operation in response to external environmental changes.

Soft Fill Operation

Prevents pump damage caused by extreme pressure change during initial operation of pumps or inside pumps.

Start Ramp & End Ramp

Prevents pump damage by changing ramps using the acceleration/deceleration time setting upon initial pump operation

Dec Valve Ramp

Prevents pump and pipe damage caused by sudden pressure changes when pumps are stopped or a pump valve is closed, Deceleration time may be set.

Multi Motor Control

MMC is used when a single drive is used to control multiple motors in the pump system.

It can control 1 main motor and 5 auxiliary motors.

Scheduling (Time Event: Real Time Clock)

Prevents pump damages caused by dramatic pressure changes during initial operation or pumps or inside pumps.

Flow Compensation

Compensates for hydraulic loss that occurs when the length of pipes are too long, adding a compensation rate depending on the inverter output frequency.

Energy-saving Display (Payback Counter)

Commercial energy consumption is compared to the amount of energy used by the drive to calculate the amount of energy saved.

Power-on Resume

When the drive restarts after it was stopped due to power interruption upon communication control, 'Power-on Resume' is used to follow the previous control command.

Sleep, Sleep Boost, Wake-up

It is used to put the drive on standby and restarts it using the amount of energy used by the drive to calculate the amount of energy saved.

Auto Torque Boost

The drive outputs voltage for the drive by controlling the level of boost to fit the load by itself.

Lubrication Control

When a control command is made in the Flow/Oiling Systems, lubrication signals are output for a certain period before the motors are started. Drive control immediately begins form the signal output point until the signals are turned off after the set time

Damper Control

When a damper exists in the system configuration, the drive will command the damper to open/close or receive feedback signals for protection.

Detection of Pipe Broken

Upon PID operation, pipe damages or leakage is detected to display a warning or a trip.

Level Detection

When the drive is operated under a frequency that is beyond the set frequency and source (voltage, current, and etc.) values to be detected are above or below the user set values, it generates a trip or activates a relay for protective operation

Pre-Heat

Pre-heats motors by direct current output when the motors are at fixed state of time in order to prevent condensation in the motors

Under Load Protection

When running pumps including no flow and dry pumps under the set frequency, the drive issues a warning function and when the trip is generated, free-run, deceleration, or stop can be selected.

Macro Setting

If a particular application is selected, frequently used parameters and set values are changed and registered in a macro group.

KEB, Kinetic Energy Buffering

Upon loss or momentary interruption of input power, if the KEB is set, the drive maintains a DC Link Voltage using regenerated energy from the motor during the interruption period.

Pump Clean

Upon pump operation, the efficiency of pumps may decline when foreign substances are stuck in an impeller. The pump clean removes foreign substances to extend pump life.

Aux Motor PID Compensation

Pipe flow increases and conduit pressure decreases as the number of auxiliary motors increases. The 'Aux Motor PID Compensation' is used to compensate pressure loss suitable for the given motor when operating auxiliary motors.

Load Tuning

Establishes load (current & power) curves based on drive frequency so as to make load characteristics curve required for 'Under Load' and 'Pump Clean.'

Fire Mode

When an emergency such as fire occurs at the suction/exhaust fans, but hardware did not fail nor has a critical defect, the drive is continuously operates to protect other systems under the set frequency and direction.

Frame Design