Preventive and periodic maintenance for capacitor Banks

Industrial revolution and fast technology development produce different type of equipment’s (Cars, Generators, Elevators, Electrical Panels, industrial machines…etc.) Those equipment’s need to be maintained by specialized engineer. with advent of this revolution, maintenance techniques need to be followed.

Industrial revolution and fast technology development produce different type of equipment’s (Cars, Generators, Elevators, Electrical Panels, industrial machines…etc.) Those equipment’s need to be maintained by specialized engineer. with advent of this revolution, maintenance techniques need to be followed.

In this article we need to focus on two maintenance techniques for Capacitor Banks Panels.

First one Periodic maintenance which is a scheduled plane with group procedures to maintain a smooth operation of equipment.

Second one Preventive maintenance which is preventing the equipment failure before it occurs.

How to apply those techniques in your Capacitor Banks Panels?

1-Periodic Maintenance:

Clean panel Air Filter every month or when it is need. Not cleaning will block the air intake, and it will not be able to cool the panel from inside, which can reduce capacitor life in result of temperature enlarging.

Every 6 months Recommissioning the Capacitor Bank Panel by below mentioned steps:

- Turn off the capacitor bank panel.

- Wait 15 mins before opening the panel door to let the capacitors discharge and avoid electric shock.

- Check fuses inside the panel visually, And test continuity by Multimeter.

- Check for lose connection on contactors.

- Check any carbon on contactor terminals.

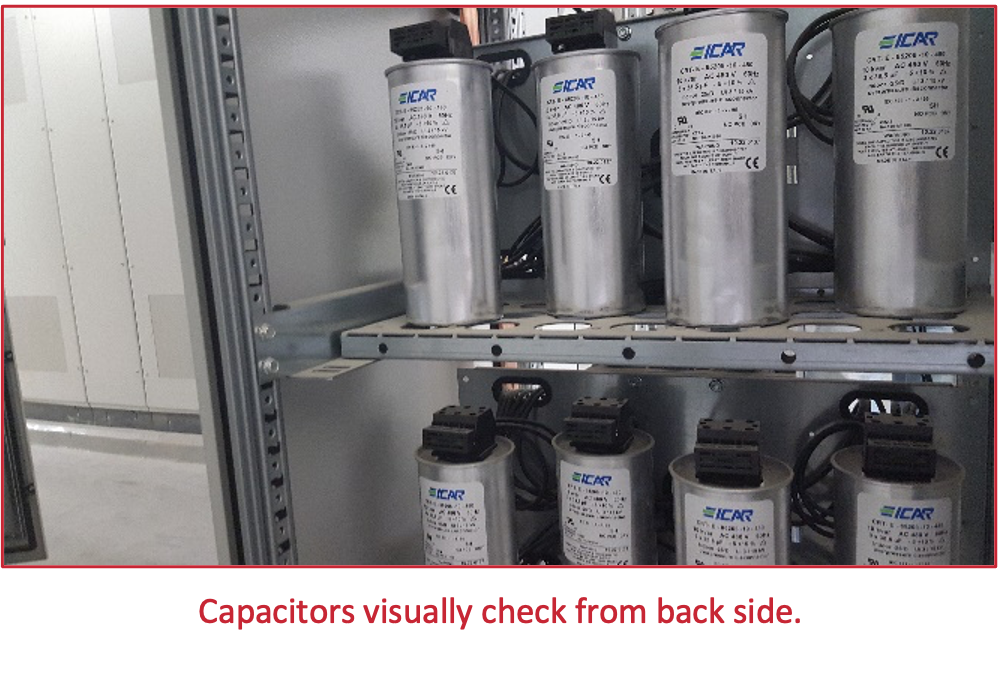

- Check visually the capacitors shape if it abnormal.

- Close the panel door and Turn on the Capacitor Bank Panel Breaker.

- Set the controller to manual mode, and make sure the factory/site is having load.

- Energized Step number 1 manually and Place the clamp-meter on out-going of Capacitor Bank Panel cable. Check the Current on all 3 phases, the reading should be approximately balanced.

- Disconnect the Step-1 and repeat point#2 for Step-2, Step-3, . . . Last Step.

- Once, the test is done successfully, switch the controller mode to “Automatic”

- Every Month Record the room temperature and make sure to be less than 30C⁰.

2- Preventive maintenance:

Mainly it is preventing any damage that might happen, prevention by analysis and monitoring the panel environment and abnormal event.

Mainly it is preventing any damage that might happen, prevention by analysis and monitoring the panel environment and abnormal event.

Example: when you are hearing power cable loose connection sound, you should search for the reasons of this.

Mostly the loose connection cause fire in your equipment.

By Doing the maintenance techniques we are targeting below mentioned benefits:

- Increasing the lifetime of capacitor bank panel.

- Maintaining the performance of capacitors. By regular periodic maintenance we do not allow the capacitors to get heated, so the performance remains great all time.

- Make sure the Air flow inside the panel work smoothly.

- Preventing the panel from damages / fire and as well as possible injury to personal; by replacing capacitors if it shapes deformed.

- Avoiding contactor overheating by removing any carbon on cable lead ends.

- Make sure that all panel’s steps working properly by doing recommissioning procedures for the capacitor bank panel.

Leave a comment