Voltage Fluctuations Effect on Industrial Facilities

The need for a steady and stable voltage supply is essential for industrial and domestic electrical appliances' safe operations. However, different factors can induce a voltage fluctuation that might lead to heavy damage to the various electrical instruments. Voltage Fluctuation is defined as a series of rapid change in the RMS voltage or a cyclic variation of the voltage waveform envelope.

When such spikes occur in the supply voltage, the electrical appliances are exposed to high voltage signals that might exceed the safe operation limits and hence damage the electrical devices. Therefore, it is necessary to stabilize such fluctuations so that a stable current and voltage flow is achieved.

Main reasons of Voltage Fluctuation are:

1- Loads with a high rate of change in their power demand with respect to the breaker short-circuit rate, such as Arc Furnaces, Rolling Mill Drives, Main Winders, etc. Also, it is important to note that even instruments with small power requirements can also be the sources of voltage Fluctuations, such as starting of induction motors, welders, boilers, power regulators, electric saws and hammers, pumps and compressors, cranes, elevators, etc.

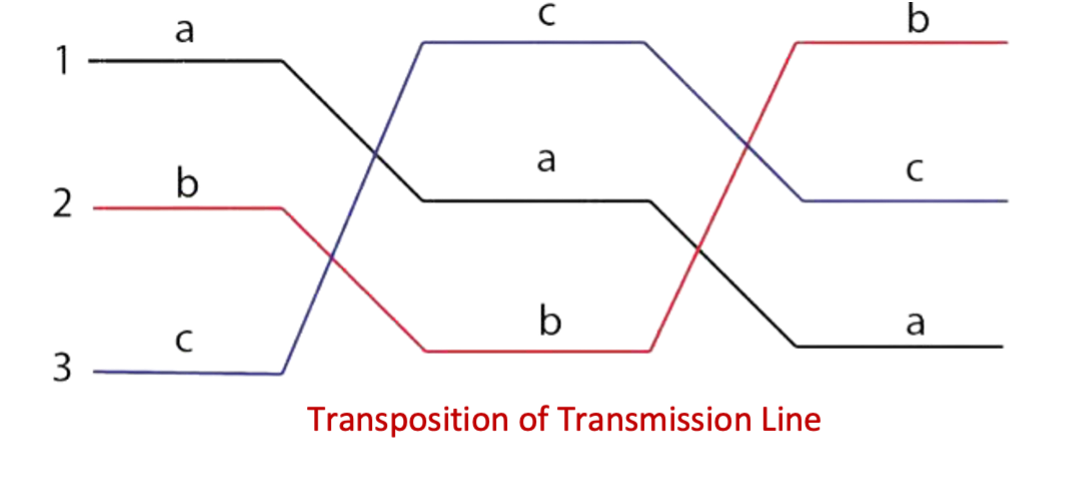

2- The conductor of the transmission lines forms a capacitor between them. The conductors act as a parallel plate of the capacitor, and the air is just like a dielectric medium between them. As a result of this, the voltage will be unbalanced.

Transposition of Transmission Line will eliminate this effect by interchange the conductor position as simply shown in the following figure. The conductor in Position 1, Position 2 and Position 3 changes in a specific arrangement.

3- Power Generation issues like:

- Unstable speed of the engine induces the fluctuation in the generated voltage of the generator set.

- If the Generator load is High; the voltage will be unstable.

- The unstable fuel circulation within the generator system causes the fluctuation in the speed of the engine, which leads to voltage instability.

Effects of Voltage Fluctuations on electrical and electronic equipment:

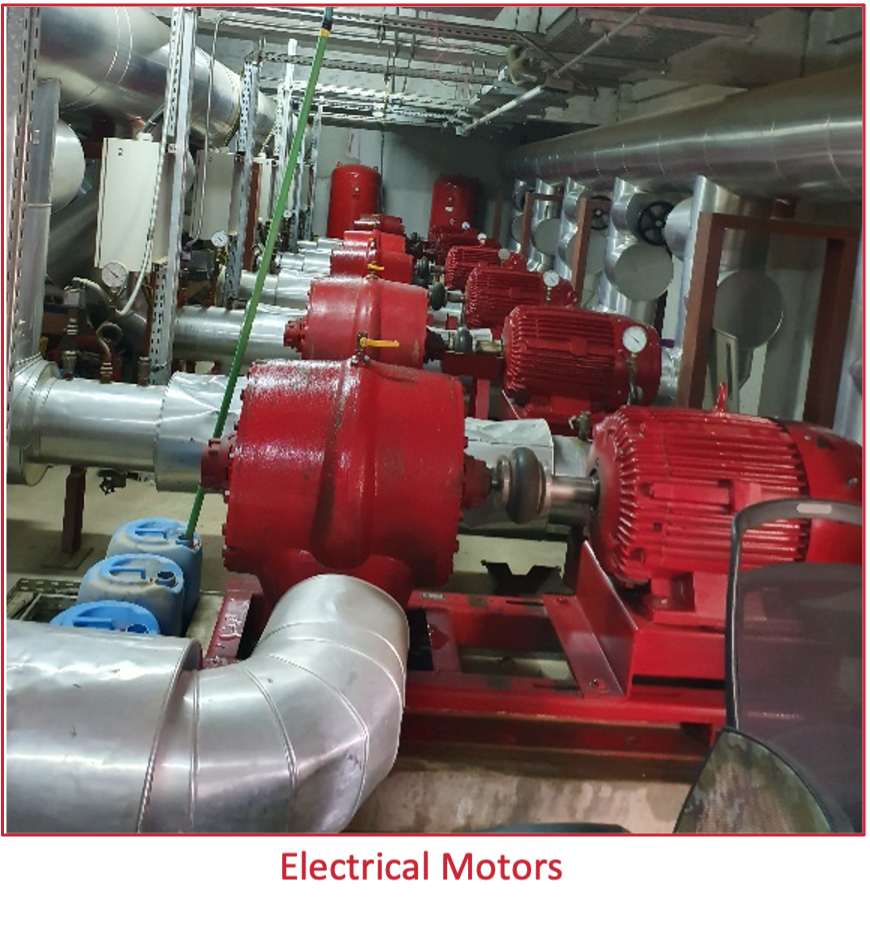

1- Electrical Machines: Voltage fluctuations at the terminals of an induction motor cause affect the output torque and slip and consequently affect the production process. In the worst case, this may lead to excessive vibration, which reduces mechanical strength and shortening the motor service life.

Voltage fluctuations at the terminals of synchronous motors and generators will lead to the following:

- Changes in torque and power.

- Increase in power losses.

- Premature wear of Motor Rotors.

- Hunting is defined as the oscillation of the rotor about its final equilibrium position.

2- Electric heating equipment:

The operational efficiency of all heating equipment is reduced in the presence of significant levels of voltage fluctuation. For example, Arc Furnace requires longer melting time when the voltage unstable.

3- Light Sources:

Any change in supply voltage magnitude results in a difference in the luminous flux of a light source. This is known as flicker.

Voltage fluctuations effect on the industrial facilities can be summarized as follow:

1- Increase yearly maintenance cost due to the frequent failure of Electrical Equipment’s.

2- Decrease the lifetime of electrical equipment.

3- Due to voltage unbalance power blackout or sensitive machine failure Will lead to:

- Increasing the production time and cost.

- Damage the manufacturing products.

Finally, the solution of Voltage Fluctuations in your facility Is a voltage stabilizer which is one of widely used solutions and it has proven to be an effective system that able to prevent potentially dangerous situations created by the unstable input voltage.

In this article we are going to explore the two commonly used stabilizers:

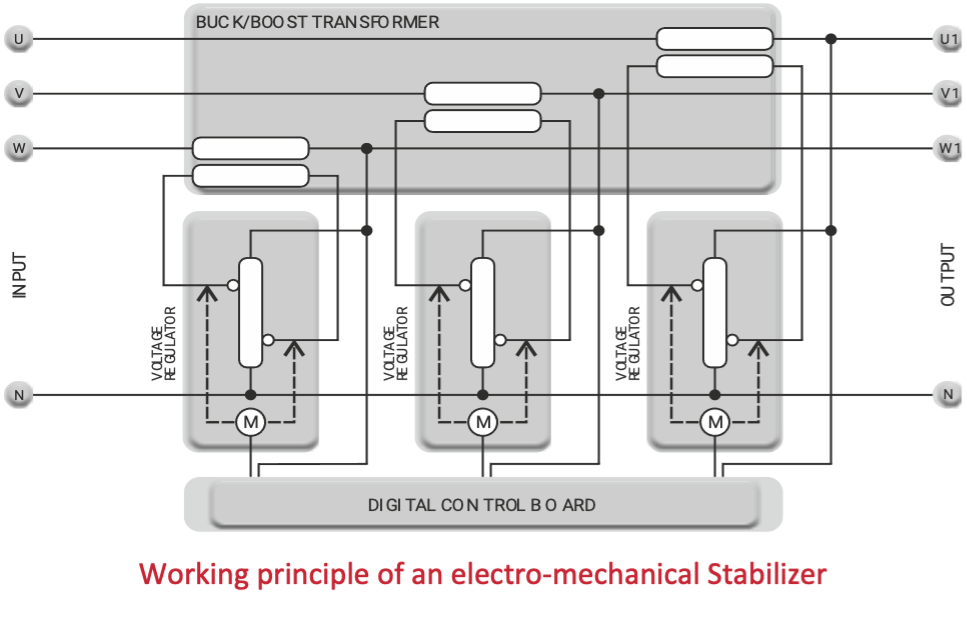

1- Electro-Mechanical Stabilizer

Which consists of a servo motor that controls the stabilization process and provides an optimal supply voltage.

Main components of this Electro-Mechanical Stabilizer:

- Continuously variable auto transformer.

- Buck/Boost Transformer.

- Auxiliary circuit with a microprocessor.

Working Principle:

When the voltage fluctuation is detected, Digital Control Board will compare the output voltage with the reference voltage level, after that Servo Motor will be moved to the desired position in the Autotransformer to maintain the reference voltage.

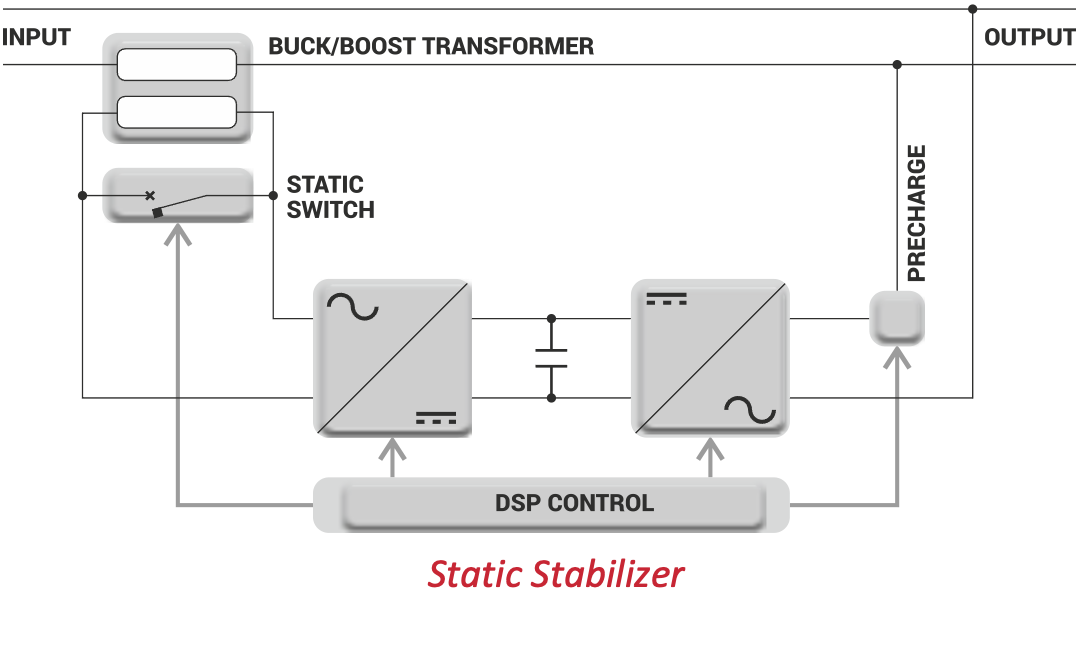

2- Static Stabilizer

The operating principle is similar to the electro-mechanical Stabilizer which described before. The difference lies in the fact that the voltage compensation on the buck/boost primary winding is performed by an electronic board through IGBT static switches instead of the Autotransformer with variable transformer ratio.

Main components of this stabilizer:

- Buck/boost transformer.

- Conversion unit.

- IGBT microcontroller-based electronic control boards.

Leave a comment